Insegne al neon personalizzate fai da te: Crea il tuo!

Indice dei contenuti

This article guides you through the process of creating your own insegna al neon personalizzata, offering a DIY approach to achieve that vibrant glow. Whether you’re looking to craft a unique piece for your casa o azienda or seeking a fun project, this guide has got you covered. This post is worth reading because it not only provides step-by-step instructions but also offers insights into using Neon a LED technology as a safer and more efficiente dal punto di vista energetico alternative to traditional neon in vetro. Learn how to design, build, and shine bright with your personalized insegna al neon.

1. Get Inspired: Ideas for Your Custom Neon Sign

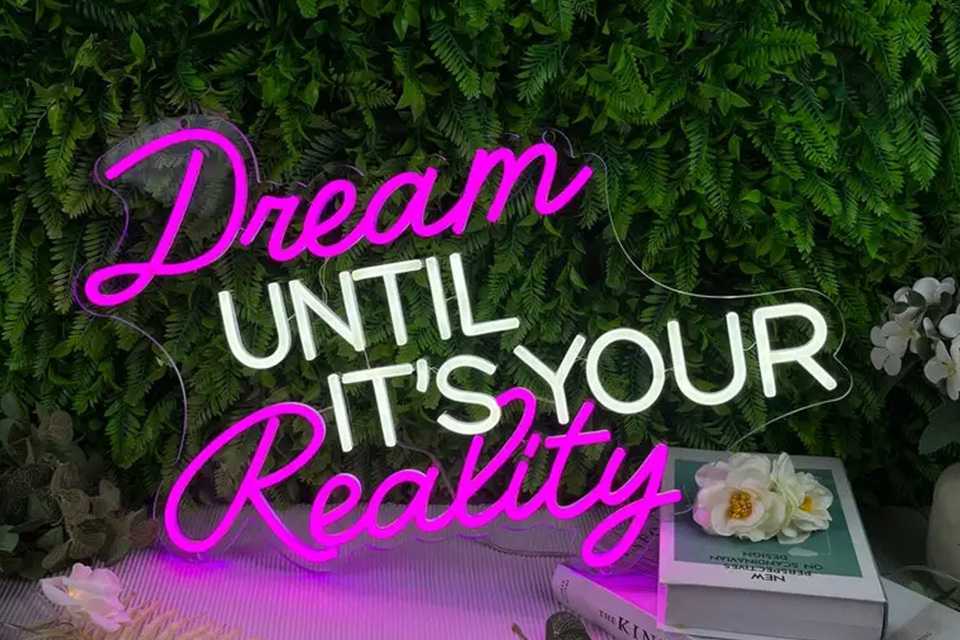

Before you create your own custom neon sign, take some time to get inspired. Think about the message, style, and colors that would best suit your needs. Custom neon lights can be a fantastic addition to your arredamento per la casa, serving as a striking pezzo forte in your living room, bedroom, or game room. For businesses, a insegna personalizzata can become an accattivante element of your branding, attracting customers and creating a memorable impression. You can find inspiration from a variety of sources. Browse online platforms, social media, and design websites to see what others have created. Consider visiting local businesses, restaurants, or insegna al neon bar aperto that use insegne al neon to get ideas for your project.

Think about the purpose of your insegna al neon. Do you want it to display a motivational quote, your name, or a unique design? For a business, your insegna al neon personalizzata could feature your logo, a catchy slogan, or a design that reflects your brand’s personality. Personalized neon name signs are very popular and effective. The colors you choose also play a crucial role in the overall impact of your insegna al neon. Neon a LED signs offer a wide range of color options, allowing you to create a design that truly stands out. An creatore di insegne al neon online can help you create a neon sign as well.

2. Step 1: Design Your Custom Neon Sign

The first step in creating a DIY neon sign is to design your insegna personalizzata. Start by sketching your design on paper. Consider the size and shape of the insegna al neon and how it will fit into your intended space. If you’re designing a sign for your business, make sure the design aligns with your brand’s aesthetic and message. Once you have a basic sketch, refine the design to make it more precise. You can use graphic design software to create a digital version of your insegna al neon, which will help you visualize the final product.

Quando si progetta la propria lettere al neon personalizzate, think about the elements you want to include. For text-based signs, choose a font that is easy to read and matches the style you’re aiming for. If you’re incorporating graphics or logos, ensure they are simple enough to be replicated with Neon a LED flex. Keep in mind that Neon a LED flex is flexible but has limitations, so avoid overly intricate details. Once you’re happy with your design, print it out at the actual size you want your insegna al neon to be. This will serve as a template for the next steps. Many neon signs that customers like are unique and reflect their personality.

3. Step 2: Gather Your Materials and Tools

Once your design is finalized, the next step is to gather all the materials and tools needed for your DIY neon sign project. For this project, we’ll be using Neon a LED flex, which is a safer, more efficiente dal punto di vista energetico, and easier-to-work-with alternative to traditional neon in vetro. You’ll need Neon a LED flex in your chosen colors, an acrylic sheet for the base, and a power supply compatible with your LED strip.

Here’s a list of materials and tools you’ll need:

Materiali:

- Neon a LED flex (in your desired colors)

- Acrylic sheet (for the base)

- Power supply (compatible with your LED strip)

- Plastic tubing (optional, for added protection)

- Strong adhesive or hot glue

- Wire connectors and electrical tape

Tools:

- Jigsaw or saw for cutting the acrylic

- Drill with various drill bits

- Screwdriver

- Solder and soldering iron

- Wire strippers and cutters

- Measuring tape or ruler

- Pencil or marker

Make sure you have all the materials and tools on hand before you start. This will help ensure a smooth and efficient process as you creare la propria insegna al neon. If you’re unsure about any of the materials or tools, consult with a specialist at a hardware store or sign shop.

4. Step 3: Prepare the Base for Your Neon Sign

With your materials gathered, it’s time to prepare the base for your insegna al neon. The base will be made from an acrylic sheet, which provides a sturdy and transparent backing for your Neon a LED flex. Start by placing your printed design template on top of the acrylic sheet. Trace the outline of your design onto the acrylic using a marker. If your design includes any internal cut-outs, mark those as well. You can make a insegna al neon a LED personalizzata using an acrylic base as well.

Once your design is traced, use a drill to create pilot holes at the corners of any internal cut-outs. These holes will help you start the cuts with a jigsaw. If your design has intricate details or sharp angles, drill additional holes along the lines to make cutting easier. Take your time during this step to ensure accuracy, as the base will determine the overall shape and structure of your insegna al neon personalizzata.

5. Step 4: Cut the Outline of Your Neon Sign

Now that your acrylic base is prepared with the design outline, it’s time to cut the outline del vostro insegna al neon. Using a jigsaw, carefully cut along the traced lines. If you’re cutting internal shapes, insert the jigsaw blade into the pilot holes you drilled earlier. Move slowly and steadily, following the lines as closely as possible. For sharp corners or tight curves, you may need to make relief cuts—small cuts perpendicular to the main line—to help the blade turn more easily.

After cutting out the main shape, go back and refine any rough edges or uneven lines. You can use a file or sandpaper to smooth out the edges and create a clean, professional-looking finish. This step is crucial for ensuring that your insegna al neon personalizzata looks polished and well-crafted. Take your time to get the shape just right, as it will be the foundation of your insegna al neon. Cut at a 90 degree angle for the cleanest edges.

6. Step 5: Attach the LED Neon Flex

With your acrylic base cut to the desired shape, it’s time to attach the Neon a LED flex. This is the step where your insegna al neon really starts to come to life. Begin by laying out the Neon a LED flex along the outline of your design on the acrylic base. This will help you determine the lengths needed and plan the placement of each section. For a insegna al neon a LED personalizzata, you might use multiple colors or sections of LED flex.

Once you have a plan, start attaching the Neon a LED flex to the acrylic base using a strong adhesive or hot glue. Apply a small amount of glue along the channel or edge of the LED strip, then carefully press it onto the acrylic, following the lines of your design. Work in small sections to ensure the glue doesn’t dry before you have a chance to position the LED flex correctly. Hold each section in place for a few seconds to allow the glue to set. If your design includes sharp bends or curves, you may need to make small cuts in the LED strip’s backing (not the LED themselves) to help it flex more easily.

7. Step 6: Solder the Connections

After attaching the Neon a LED flex to the acrylic base, the next step is to solder the electrical connections. This step requires careful attention to detail to ensure your insegna al neon functions correctly and safely. If you’re using multiple sections of Neon a LED flex, you’ll need to connect them in a series or parallel circuit, depending on your power supply and the specific requirements of your LED strip. Use a soldering iron to join the wires, making sure to create secure and clean connections.

Once the sections are connected, you’ll need to connect the Neon a LED flex to the power supply. Follow the manufacturer’s instructions for your specific LED strip and power supply to ensure proper wiring. Typically, you’ll connect the positive wire from the LED strip to the positive terminal on the power supply and the negative wire to the negative terminal. Double-check all connections to ensure they are secure and properly insulated with electrical tape or heat-shrink tubing. Incorrect wiring can damage your LED strip or create a safety hazard, so take your time and double-check your work.

8. Step 7: Test Your Neon Sign

Before finalizing the assembly of your insegna al neon personalizzata, it’s crucial to test it to ensure everything is working correctly. Connect the power supply to a power outlet and turn on your insegna al neon. Il Neon a LED flex should light up, creating the vibrant glow you’ve been working towards. Inspect the entire segno to make sure all sections are illuminated evenly and that there are no flickering or dim areas. This is your chance to identify any issues with the wiring or connections.

If you notice any problems, such as sections not lighting up or flickering, turn off the insegna al neon and carefully inspect the connections. Look for any loose wires or areas where the solder joints might be weak or broken. Re-solder any faulty connections and test the segno again. It’s better to catch and fix any issues now before you complete the final assembly. Once you’re satisfied that everything is working correctly, you can proceed to the final steps.

9. Step 8: Final Touches and Mounting

With your insegna al neon tested and working, it’s time to add the final touches and prepare it for mounting. If you want to give your insegna al neon personalizzata a more polished look, consider adding a backing or frame. This can be made from a variety of materials, such as wood, metal, or acrylic, depending on your design and preference. A backing can also provide added support and protection for the Neon a LED flex and wiring. You can make insegne al neon personalizzate to add a nice touch to your home.

To mount your insegna al neon, you can use a variety of methods depending on the size and weight of the segno and where you plan to display it. For smaller signs, adhesive strips or hooks might be sufficient. Larger signs may require more robust mounting hardware, such as screws or brackets. Ensure that the mounting method you choose can adequately support the weight of your insegna al neon and that it’s securely attached to the wall or other surface. Before drilling any holes, use a level to make sure your insegna al neon will hang straight.

10. FAQs About Making Your Own Neon Sign

Can I create a custom neon sign without any experience? Yes, with the availability of Neon a LED flex and detailed guides like this one, even beginners can create their own insegna al neon personalizzata. The process involves basic crafting skills, and no prior experience with traditional neon in vetro is required.

Is it safe to make a DIY neon sign? Using Neon a LED flex is generally safe, as it operates at low voltage and produces minimal heat. However, always follow safety precautions when working with electrical components and tools.

How long does it take to make a custom neon sign? The time required can vary depending on the complexity of the design and your experience level. On average, it might take a few hours to a full day to complete a DIY neon sign.

Can I use any type of LED strip for a neon sign? It’s best to use Neon a LED flex specifically designed for this purpose. It’s more flexible, durable, and provides a continuous line of light that mimics the look of traditional neon.

What is the best way to cut an acrylic sheet for the base? A jigsaw is the most common tool for cutting acrylic sheets. Move slowly and steadily, and use relief cuts for sharp corners or curves.

How do I power my LED neon sign? You’ll need a power supply that is compatible with your Neon a LED flex. The power supply converts household electricity to the low voltage required by the LED.

Can I make a multi-colored neon sign? Yes, you can use different colors of Neon a LED flex to create a multi-colored design. You can connect them in separate circuits or use an RGB LED strip with a controller for more dynamic color options.

What should I do if my neon sign doesn’t light up? Check all connections, including the wiring between LED sections and the power supply. Ensure the power supply is working correctly and that all solder joints are secure.

How do I mount my finished neon sign? Mounting methods vary depending on the size and weight of the segno. Options include adhesive strips, hooks, screws, or brackets.

Where can I buy materials for a DIY neon sign? Materials like Neon a LED flex, acrylic sheets, and power supplies can be found at hardware stores, online retailers, and specialty sign shops.

Conclusione

- Creare un insegna al neon personalizzata using Neon a LED flex is a rewarding DIY project suitable for various skill levels.

- Start by getting inspired and designing your insegna al neon, considering its purpose, style, and colors.

- Gather necessary materials and tools, including Neon a LED flex, an acrylic sheet, a power supply, and basic crafting tools.

- Prepare the acrylic base by tracing your design and cutting it out carefully using a jigsaw.

- Attach the Neon a LED flex to the acrylic base using strong adhesive or hot glue, following your design outline.

- Solder the electrical connections between LED sections and the power supply, ensuring secure and properly insulated joints.

- Test your insegna al neon before final assembly to identify and fix any issues with the lighting or connections.

- Add final touches like a backing or frame, and choose an appropriate mounting method for your insegna al neon.

- Neon a LED flex offers a safer, more efficiente dal punto di vista energetico, and flexible alternative to traditional neon in vetro for DIY projects.

- Refer to the FAQs section to troubleshoot common issues and find answers to frequently asked questions about making your own insegna al neon.

By following these steps and tips, you can create a stunning insegna al neon personalizzata that adds a unique and vibrant touch to your home or business. Enjoy the process and the satisfaction of seeing your DIY neon sign shine bright!